IMAGINE

- your customers are your best supporters

- all of your employees know their customers and actively find ways to better serve them

- leaders-at-all-levels collaborate to prepare their annual improvement action plans, then translate and deploy those plans into workplace initiatives

- leaders and process owners work together to solve problems and share a sense of purpose

- continuous improvement is part of daily work

- an organization of networked teams, enabled and continuously increasing stakeholder value

What you are imagining is a Lean Enterprise in motion™

Marrying the Technical and Social

A Lean Enterprise in motion is a multifaceted concept that operates on two primary dimensions, each contributing to a holistic approach to achieving operational excellence.

The Lean Production System

The first and perhaps more familiar dimension is the lean production system. This dimension integrates various tried-and-true methodologies, such as total quality management, six sigma, total productive maintenance, and just-in-time. It’s a comprehensive toolbox of lean manufacturing tools and waste elimination techniques designed to optimize the balance between cost, quality, and delivery. By leveraging this technical dimension, a Lean Enterprise in motion™ ensures an optimal mix that enhances customer experiences while achieving target margins. This lean production system guides the ‘what’ in the pursuit of operational excellence.

The Lean Management System

The second dimension of a Lean Enterprise in motion™ is the lean management system. This aspect encompasses two critical components. Firstly, it encompasses a lean infrastructure that consists of a dynamic network of team structures, communication programs, visual management systems, and information flows. This infrastructure creates a high-performance workplace environment, fostering collaboration and enabling efficient operations. Secondly, the lean management system focuses on leadership, culture, and strategic alignment. It integrates elements like the voice of the customer, Hoshin Kanri (policy deployment), and strategy formation. This social dimension governs the ‘how’ by harmonizing the entire organization, ensuring that every individual is aligned with your overarching business and improvement objectives.

In essence, a Lean Enterprise in motion™ harmoniously marries the technical and social dimensions, resulting in a dynamic, well-balanced system that optimizes both processes and people. By synergizing these dimensions, organizations unlock the true potential of Lean, creating a sustainable path to operational excellence.

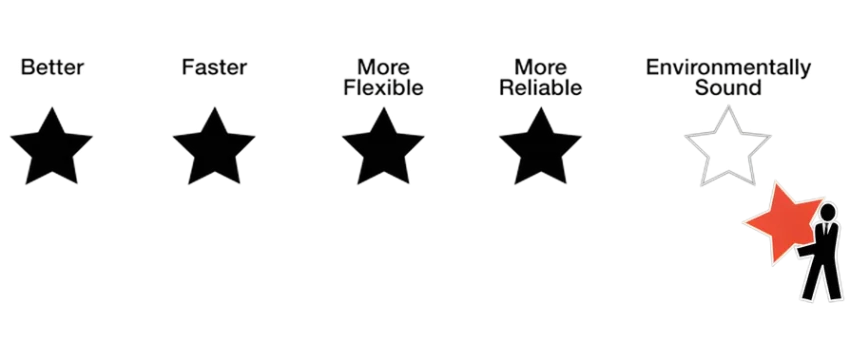

By becoming a Lean Enterprise in motion™, organizations unlock heightened efficiency, improved customer satisfaction, and sustained growth.