An Article From the Archives:

Reduced downtime. Greater capacity. Increased yield. Higher revenues. According to Darrell Birks, maintenance supervisor at MEMC Electronic Materials (St. Peter’s, MO), you can get all this quickly, simply and with minimal expense. All you need are creative ideas from your shop-floor people and an ample supply of “sticky notes.” In this month’s article taken from the Productivity TPM Newsletter, January 1992, we learn how one organization used CEDAC to manage improvements within their organization.

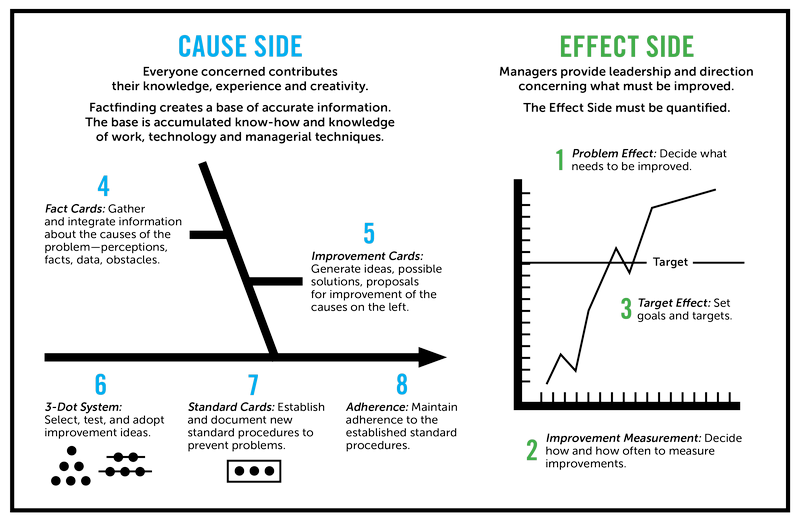

The eight stages of continuous improvement as reflected in the CEDAC® diagram.

The technique is called CEDAC,® or Cause-and-Effect Diagram with the Addition of Cards. Birks says it’s a great way to solicit, organize and implement improvement ideas in maintenance–or any other department. The diagram above shows a schematic of the eight-step CEDAC process.

CEDAC core groups at MEMC, a silicon wafer manufacturer, typically consist of six to eight people representing all functions involved in the problem under investigation. Most CEDAC projects arise from monthly quality improvement meetings (QIMs). “At maintenance QIMs, we talk about real-time problems that affect mechanics,” says Birks. Those same problems, he adds, usually affect operators.

As QIM teams brainstorm, they often suggest applying CEDAC to a specific problem. “They first establish where they are and where they want to go,” says Birks. “The CEDAC goal [i.e., the “target effect” in the above diagram] is reached by team consensus; it’s not dictated,” he emphasizes.

Birks and MEMC first learned about CEDAC in 1986 from Japanese management expert Dr. Ryuji Fukuda. Maintenance took the lead in CEDAC implementation, and its success has incited all other MEMC departments to adopt the method.

The bottom-line benefits in 1986 alone were startling. Birks reports that CEDAC contributed much to the 0.6% yield increase that year. That may seem like peanuts, but in the silicon wafering business, a 1% improvement in yield equals tens of thousands of dollars per month in increased revenue.

Mount-Line Improvements

One significant maintenance related CEDAC success occurred on the mount line, which prepares and loads wafers for polishing using conveyors, mechanical arms, steam pots, and robots.

Why focus on the mount line? With the plant at capacity and customers demanding more product, QIM teams analyzed the entire wafering process and identified the mount line as a primary bottleneck.

At the time, maintenance considered the 3% mount line unplanned downtime “acceptable,” says Birks. But the mount-line CEDAC core group estimated that a downtime reduction to 1% would “enable us to load 1,000 more blocks (each of which holds four to eight wafers) per month,” Birks says. “That’s lots of extra capacity and revenue.”

The core group broke the mount-line process into three sub-processes and made a CEDAC board for each. More importantly, they decided on the number of equipment stoppages as the improvement measurement.

“We usually track down-for-maintenance (DFM) percentages,” says Birks. “But operators told us that most of the mount-line stoppages were short, so we focused initially on the total number of stoppages. We figured we could do another CEDAC later with time as the measure if we had to.”

The core group set the goal of two stops per shift. They graphed the current level of stoppages on the CEDAC board and posted it next to the information center, visible to all operators and maintenance people in the mount-line area. The ideas came in abundance.

“There wasn’t a single idea that we didn’t implement,” recalls Birks. “Most were quick and inexpensive.” Some results:

- MEMC cut the changeover time-from 15 minutes to 2 – for the squeegee that wipes water off the block before it goes into the vacuum chamber. Changes in the material of the squeegee prolonged its life and reduced setup frequency.

- Grippers in the transfer units were redesigned to prevent slips and misalignments.

- MEMC reduced the number of PLC-controlled sensors. The sensor near the steam pot had been a particularly troublesome downtime culprit. Removing that sensor reduced stoppages for sensor replacement and had no effect on process-control reliability.

- MEMC asked suppliers for harder spin-station shafts, chuck keys and conveyor belt rails. Wear from milder steel caused repeated misalignments and stoppages. Birks says, “The steel hardening was the most expensive CEDAC improvement in this case.”

- Transfer-arm bearing failures had been common, largely because workers had to remove the arms to get at lubrication points. CEDAC led to the addition of Zerk fittings so the bearings could be lubricated with the transfer arm in place. “That increased bearing lifetimes from a year and a half to six or seven years,” says Birks.

Birks emphasized that CEDAC is a continuous-improvement tool. Even though MEMC takes down its CEDAC boards when 70-80% of a problem is solved, the company always records them.

“We photograph the board or save it on a computer file,” says Birks. “We’ve seen ‘solved’ problems recur one or two years after a CEDAC because people and operations change, no matter how much you try to standardize them. The old boards act as a benchmark that we can refer to.”

A more recent CEDAC project focused on the single-sided scrubber systems that clean wafers prior to shipping. Maintenance was receiving 200-250 work orders on these every month. Though each job usually took only about five minutes and the total DFM was a mere l.4%, maintenance QIM teams felt that scrubber problems interfered with other, more important maintenance work.

The QIM team sought to cut the number of scrubber work orders in half. With CEDAC, the number of monthly work orders dropped to 140 within three months.

Three-Color Card System

CEDAC is a highly visual tool, using yellow problem or fact “cards” (sticky notes) and blue solution cards. Birks says, “We get yellow cards from people by asking what keeps them from doing their job better, or what they would change or improve if they had the opportunity.” He says CEDAC has induced an interesting culture reversal: “We once told people to follow procedures,” Birks says. “Now we want them to question procedures.”

On many of the CEDAC boards hanging at MEMC, red summary cards connect with yellow problem cards. Birks explains: “When the board gets cluttered with yellow cards, it’s hard to see the connection between problem and solution cards. So we group yellow cards according to a trend or focus. Then we write a statement that summarizes that group of problems and put it on a red card That makes it easier to generate good solutions.”

At MEMC, anyone in the plant can write a card and post it to the CEDAC board, even if they’re just passing through an area. The core group considers and answers every blue solution card with a posted, written comment.

Prioritizing Ideas

Early on, CEDAC core groups received complaints from some suggestors who were impatient to see their ideas implemented. So the company created prioritizing criteria to help standardize testing and implementation of CEDAC ideas. “This helps explain to everyone how core groups select solutions,” says Birks. “Now people know that it has nothing to do with personalities or grade levels.”

Birks says that MEMC gives highest priority to workable ideas that benefit operators. Conversely, Birks observes that “the simplest, least costly, most effective and rapidly implementable ideas usually come from operators.”

Self-Improvement Time

MEMC’s maintenance supervisor Darrell Birks has allocated one hour per week of “self-improvement time” for all maintenance personnel. “I checked with top managers from the wafering area and got their buy-in to the idea,” says Birks. “If the results are good, I think we’ll get more than an hour.”

Techs use self-improvement time to read books or journals, watch instructional videos, organize their tool boxes, or learn spreadsheet software. “I left it wide open,” says Birks, “but I made it clear that tasting the food at local restaurants would be inappropriate.”

Birks asks all maintenance personnel to turn in a three-by-five note card with a brief description of how they use their hour every week. Maintenance staffers select their own self-improvement times by coordinating with one another and with the maintenance schedule.

CEDAC Flexibility

Birks likes CEDAC because it can be applied to any problem. A core group is now using CEDAC to reorganize the maintenance shop in an effort to optimize space.

In its most all-inclusive use of CEDAC to date, MEMC created an eight-legged CEDAC diagram that focuses on small, often-ignored problems in the wafering process. Says Birks, “The goal is to eliminate the little irritations that people think they have to put up with.”

Although Birks swears by CEDAC as an improvement tool, he encourages anyone using it to mold it toward their particular needs. “Be creative with CEDAC,” he recommends. “Use it like a set of troubleshooting instructions, as a guide.”