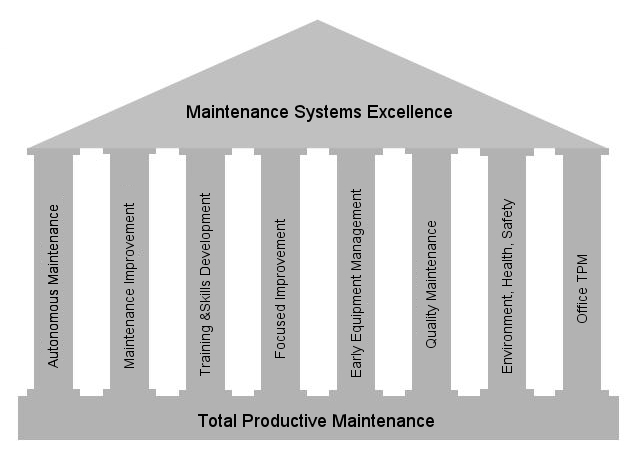

Total Productive Maintenance (TPM) is a systematic approach to equipment maintenance designed to optimize equipment availability and performance. The core principle of TPM revolves around engaging every member of the organization in the process of maintaining equipment.

TPM is built on eight essential pillars:

- Autonomous Maintenance: Empowers operators to conduct basic equipment care and routine maintenance tasks on their assigned equipment.

- Maintenance Improvement: Shifts the focus of the professional maintenance team from reactive firefighting to planned preventive maintenance activities.

- Training and Education: Ensures that staff possesses the necessary skills and understanding to effectively support TPM initiatives.

- Focused Improvement: Drives cross-functional teams to address targeted or chronic losses through coordinated efforts.

- Early Equipment Management: Enhances equipment design and manufacture for easier operation, simplified maintenance, and optimal sizing for intended usage.

- Quality Maintenance: Addresses the root causes of defects and enhances product quality by maintaining equipment throughout the production process.

- Environment, Health, and Safety: Prioritizes preventing human errors, eliminating accidents, addressing workplace hazards, and reducing resource waste.

- Office TPM: Extends TPM principles to administrative functions, strengthening departments through continuous improvement activities.

Implementing TPM can yield significant advantages for organizations, including:

- Reduced Equipment Failure and Downtime: Minimizing unexpected breakdowns and disruptions.

- Extended Equipment Lifespan: Prolonging the productive life of machinery.

- Enhanced Workplace Safety: Ensuring a safer work environment for all personnel.

- Lower Maintenance Costs: Reducing expenses associated with reactive repairs.

- Increased Productivity: Optimizing equipment performance for higher output.

TPM is a highly effective approach to enhancing equipment reliability and uptime. If you’re seeking ways to elevate your organization’s equipment and process reliability, TPM stands as a compelling solution to explore.