Pharmaceuticals, Human and Animal Healthcare, Bio-tech environments, Cosmetics, Chemicals, Food industries, R&D…

The Lean laboratory certificate program is designed to start you on the path to continuous improvement in your lab! Learn how to manage flows, eliminate backlogs, rework, and other inefficiencies while improving service to production, supply chain and customers and increasing employee satisfaction.

Why is Lean important in lab environments?

Because a laboratory is involved at each step of the Value Stream — incoming materials and goods, work-in process, and semi finished and finished products — delays and errors have a negative impact on the entire organization. Therefore speed, reliability and quality, i.e. lab efficiency, have a direct impact on overall organizational efficiency, as well as costs and the ability to meet customer demand.

Furthermore, specialized skills needed in the laboratory make it specially devastating for the organization when individual technicians leave due to an inefficient stressful process and environment.

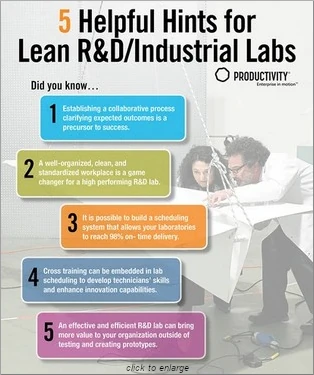

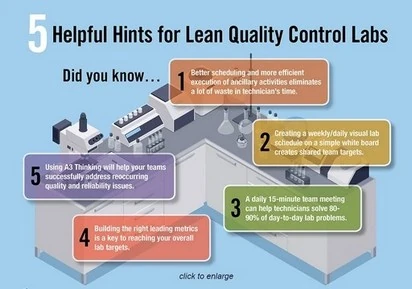

Applying Lean in a lab environment helps alleviate inefficiencies by:

− Improving end-to-end processes (Value Streams)

− Underscoring demand and its variability

− Scheduling analysis flows based on demand

− Defining resources required

− Creating and sharing standards to reduce rework

While

− Creating a working environment based on trust, empowerment, and teamwork

− Upskilling through cross-training

− Developing problem-solving skills

The Lean Lab concepts apply to all laboratories including Production Labs, Quality Control, Quality Assurance, and R&D.

Curriculum

Monday 10:30am-5:30pm Eastern Time

- Lean Fundamentals in Labs Environments

- A3 Thinking

- High Level Process Mapping

- Learning to See Waste in Labs

Tuesday 10:30am – 5:30pm Eastern Time

- Mapping and Improving the Value Streams

- Understanding Incoming Laboratory Demand

- Defining Product Families in Laboratories

Wednesday 10:30am – 5:30pm Eastern Time

- Planning and Scheduling to Optimize Man and Equipment Time

- Building Visual Management for Analysis Flows and Lab Activities

- Workplace & System Organization: 5S’s, Visual Standards and Standardized Work for Process Stability

Thursday 10:30am – 5:30pm Eastern Time

- Reducing Set-up Times

- Establishing metrics: Leading and Lagging KPI’s

- Daily Performance Management

- Team-Based Problem-Solving

Friday 10:30am – 12:30pm Eastern Time

- Week in Review

- Taking it Back Home: Outlining Your Implementation Roadmap

Discover how Lean can help:

- Continuously improve customer satisfaction by improving quality at the source and reducing lead-time for your customers

- Systemically and repeatedly identify process inefficiencies so they can be reviewed and eliminated

- Eliminate back-logs and failure demand – the work created when an activity is not carried out correctly the first time

- Level the analysis flows to respond to incoming demand

- Reduce absenteeism and turnover by creating more value-added work

- Make processes visible so everyone can monitor daily progress to achieve improvement goals

- Increase process capacity so more value-adding work can be performed with existing resources

You will understand how these principles apply to your laboratory processes and how you can develop your “leadership legacy” through the implementation of these Lean approaches.

“Positive, I really enjoyed the instructor. She kept the class involved with effective questions. She prepared questions each morning about items we discussed the day before that really highlighted the key things to take away which helped. The part I appreciated the most was applying these LEAN principles to our own companies with her feedback and highlighting key parts.”

Steven Y. , QC Micro Supervisor – Lifecore Biomedical

“The class has been very informative for lean opportunities in a lab environment.”

Mark O., Electronics Lab Supervisor – Neptune Technology Group

“I plan to assess the current state of my lab using the tools from the training and plan implementation opportunities. I will be mapping the total process time to get a better understanding of the processes. I hope to implement several improvements in the next few months.” “I very much enjoyed this class. I will be recommending this class to my laboratory colleagues.”

Jeff S., QC Chemistry Supervisor – Lifecore Biomedical

“I wanted to let you know that after 7 years of work, we have been awarded the Shingo Prize, the real one.

We are happy to have achieved this very ambitious goal and to be the first French site to have it and only the second pharma site in the world. A great adventure! We will accept the prize in April in Florida. Thank you again for your contribution over the years 2013-2016 which made it possible for us to build solid fundamentals in Visual Management and Lean Lab.”

-A.B., Global Manufacturing Performance Senior Director TechOps Division, Ipsen Pharmaceutical Company