Leadership & Management Systems

A Lean enterprise develops leaders at every level to manage change and drive results.

An Effective Management System Begins with Capable Leaders

We can assist you in developing leaders at every organizational level.

CREATING A SYSTEMIC PROCESS FOR DEVELOPING AND THEN DEPLOYING

- Transformational leadership capabilities of strategic alignment

- Engagement/empowerment

- Teaching and learning

- Gemba walks

- Problem-solving

- Necessary daily management to ensure long-term success

Executive Coaching

Developing the Lean Enterprise requires transforming busy executives into Lean executives capable of sharing the “Why change”, providing clarity on where the company is going, establishing the balance between short and long-term goals, and creating the organizational infrastructure and processes to ensure a customer-oriented company culture.

What We Do

Our executive coaches, all former Lean leaders, work closely with key executives and senior management to create a leadership development playbook consistent with their roles and responsibilities.

How You Succeed

The outcome is leaders’ ability to understand the need for change and effectively act to drive the company to short and long-term success.

Manager and Supervisor Training

In a Lean enterprise, the primary role of the manager and supervisor turns from that of “doer” to that of “mentor”, creating the framework that allows field team members to act freely in deciding how to do their work, address problems, and develop. This can often be a difficult transition.

What We Do

Productivity works with managers and supervisors in on-the-job skill development sessions to help in this transition. Sessions also cover interpersonal skills, recognition, rewarding systems, pay for performance, team evolution, performance of value flows, measurement and auditing, and more.

How You Succeed

Your team will enhance their understanding of problem-solving, standard work, daily management, and other fundamental Lean ways of working while improving their confidence to lead.

Team Development

Improving team performance is a must for Lean success. An empowered team-based environment is one in which leaders provide the “what” needs to be done and “why,” and associates are given the support and freedom to determine the “how.”

What We Do

Productivity works closely with you to create the framework for team structures.

How You Succeed

This network of teams, managing daily work, opening and closing projects, and solving problems creates an organic learning environment that keeps your enterprise in motion – continually learning, providing better customer experiences and innovating quickly.

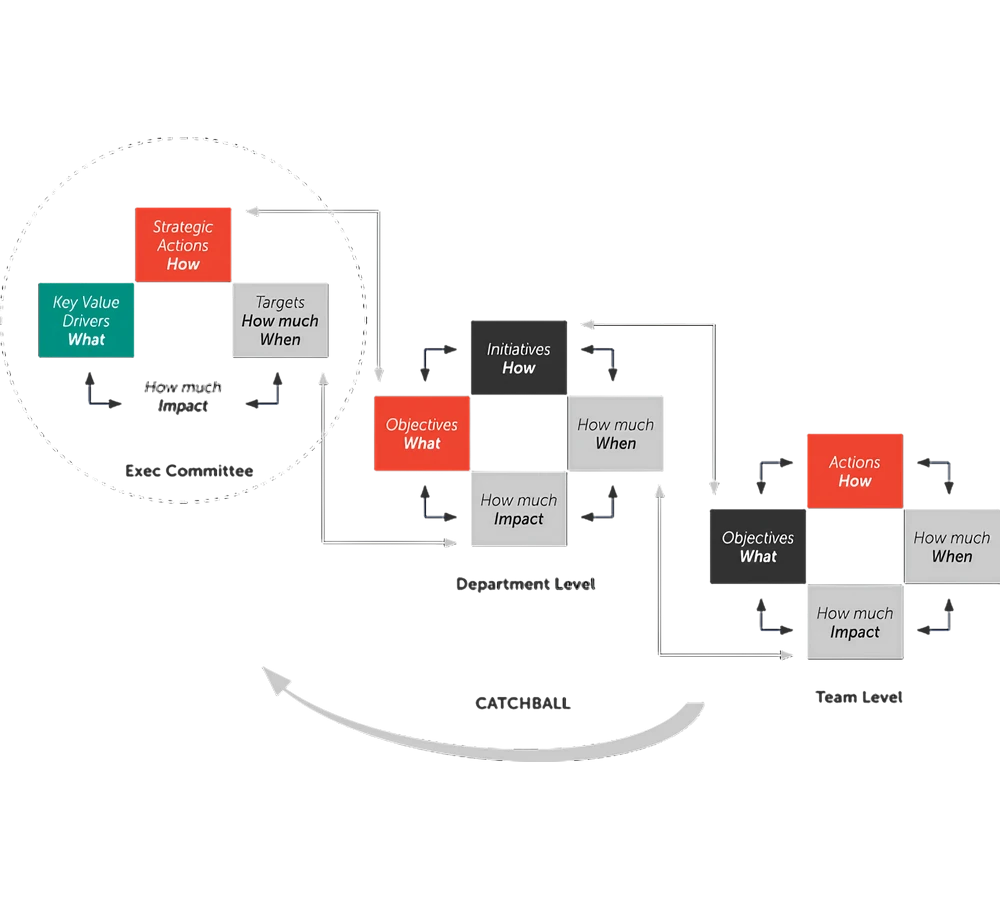

HOSHIN KANRI

We partner with you in the development or refinement of your high-level strategic plan, then to deploy that plan and its objectives within your organization. This will link strategy with daily work, and highlight everyone’s role in the improvement process.

Contact us to learn more about how hoshin kanri and the X-Matrix connects organizational goals to daily work and allows everyone in the organization to understand how their individual efforts contribute.

Explore our paper to learn more about Hoshin Kanri:

Introduction to Hoshin Kanri – Policy Deployment / Strategy Deployment

“Wanted to reach out to you personally to thank you for the excellent training in October. I have used it heavily in my communication to our organization including completing our first bonafide CEDAC yesterday. The mind shift on problem-solving has helped my leadership style and coaching tremendously. Thank you for your excellent program.”

– Heather F., Director of Operations, Composite Advantage

News & Resource Library

Check out our white papers, case studies, and view our implementation experiences in our news & resource library.

Explore Our LibraryCertification & Training

Think you'd like to get Lean certified? Explore upcoming educational programs or on-site Lean training for your team.

Browse Programs