If your value-streams are capital equipment intensive, developing an internal Total Productive Maintenance (TPM) resource will help you eliminate the equipment reliability issues—breakdowns, minor stops, long changeover adjustments, and other inefficiencies—that are hurting your competitiveness.

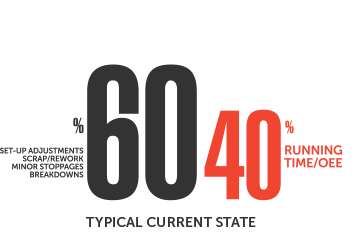

When moving from 40% OEE to 85% OEE you can double your capacity with no capital investment. And that’s just one benefit of successful implementation of Total Productive Maintenance (TPM), other gains include:

Technical benefits such as…

- Productivity improvement of more than 35%.

- Increased equipment effectiveness from 50-70% to 80-90%.

- Unplanned downtime (breakdown & minor stoppages, etc.) reduced by about 80%.

- Reduced quality defects by up to 50%.

- Scrap reductions of approximately 65%.

Social benefits such as…

- Motivated workers committed to improvement.

- Goal oriented efficient teams.

- Pro-active, solution oriented thinking and acting.

- Safe and stable operating environment.

Equipment and process reliability are too important to your business success not to have a TPM effort and a well-trained TPM Manager to guide the implementation.

This highly interactive, fully accredited program is designed for corporate and plant personnel looking to learn, launch, and lead a proven, systemic, equipment and maintenance management improvement process—Total Productive Maintenance (TPM). Combining classroom learning with simulations, group exercises, targeted discussion sessions, and shopfloor application, TPM practitioners deep dive the concepts and tools of TPM and share lessons from their implementation experiences.

Participants learn how to establish the daily management behaviors that will sustain TPM

and ensure alignment with overall improvement and Environmental, Health, and Safety goals.

Fully accredited certification for TPM managers and reliability leaders since 2010.

Over four non-consecutive weeks, attendees participate in a series of learning modules focused on the three critical areas for success: Planning, Doing, and Leading.

Between session weeks on the campus of The Ohio State University’s, students implement TPM projects at their own companies and present results during the next session week.

Curriculum

The TPMC curriculum is divided into four, 1-week sessions focused on planning, implementing, and leading a TPM initiative.

These week-long sessions are spaced over approximately 4 months. During the three intervening weeks between each session week on the campus of The Ohio State University, participants apply learning on the job and present results at the following session.

TPMC – Week 1

In TPMC Week 1, essential concepts and foundations of TPM and managing a TPM rollout are instilled in participants. Learn the eight pillars of TPM, how TPM integrates with and builds upon improvement strategies, and how to assess the current state and create a TPM roadmap and 12-step TPM rollout process.

Modules include: Context and Strategy—TPM as an Enabler; The Zero Failure Principle and the Pillars of TPM; The Master Plan; Value Stream Analysis; Focused Improvement; Project Chartering and Project Management

TPMC – Week 2

The success of your TPM initiative depends on skillful leadership of the change process at all levels. TPMC Week 2 kicks off with the best ways to build an initiative that will become ingrained in the organizational culture. The week continues with more in-depth training and practice in TPM methods and tools.

Modules include: TPM Leadership; 5S/Visual Workplace and Mistake Proofing; Autonomous Maintenance; Standard Work for TPM; Six Sigma (DMAIC, SIPOC); Plant Application Exercise; Set-Up Reduction / Quick Changeover (The SMED System).

TPMC – Week 3

The maintenance improvement and training/skills development pillars of TPM are covered during TPMC Week 3. The goals are to move away from reactive to proactive or planned maintenance, and to train staff in an effective way that increases capabilities while reducing training costs.

Modules include: Maintenance Improvement (including Stores Management; Maintenance Planning and Scheduling; Maintenance Skills Development; Predictive Maintenance Tools, Maintenance Scorecards, and the Computerized Maintenance Management System, or CMMS); Plant Application Exercise; Training and Skills Development.

TPMC – Week 4

The final week of TPMC delves into the critical role of the TPM manager in the change process, teaches a system for auditing and accountability, and covers the last four pillars that extend the TPM process beyond the basics and off the production shop floor: quality maintenance, EHS, administrative TPM, and early equipment management. Final project summaries are presented, bringing the learning back to the reality of on-the-job application.

Modules include: Machine Failure Analysis, TPM Manager – Facilitator and Coaching Skills; Quality Maintenance Round Table; Environmental Health and Safety, and Going Green; Office TPM and Support Systems; Early Equipment Management; TPM Audit and Accountability.

Module descriptions are available on the event brochure.

TPMC graduates will gain overall knowledge of the eight pillars of TPM and will be able to:

- Establish and customize a strategy for implementing TPM

- Properly use machine performance data to identify and execute a tactical action plan

- Justify and implement a complete maintenance planning and scheduling process

- Conduct and lead autonomous maintenance kaizen events

- Design and perform site-specific TPM auditing processes

- Establish a baseline data collection process and understand how to use the OEE metric

- Conduct breakdown analysis reviews, and grasp their importance

- Organize and control spare parts

- Use the principles of Early Equipment Management

WHAT PAST ATTENDEES ARE SAYING…

“This training has been foundational in helping our leadership team understand TPM and the tools available to drive improvement. Ellis has done a great job the last 3 sessions and helped make the business case for Mars Petcare to further invest in the program.” Lucas T., – Supply Excellence Manager – Mars Petcare

“The TPM Certification training was one of the most rewarding accomplishments of our professional careers. It has given us the knowledge, skills, and inspiration needed to make some positive changes in the way maintenance is carried out at Miba. We are also looking forward to continuing our Lean training with Productivity Inc at Ohio State University this Spring.” Troy A. and Brent G., – Production Support Engineers – Miba Bearings US

“It is the most useful education for my career to date.” Keith D., – TPM Manager – MI Windows & Doors

“Well planned and delivered in both theory and application. I felt the plant visits were critical to providing the experiential knowledge needed to truly understand the concepts.” Michael S., – Black Belt – Delta Airlines

![]()

PRODUCTIVITY INC.

Productivity Inc. is a leading consulting and training firm that helps organizations build new capabilities, save money, and grow. We focus on three progressive strategies: Operational Excellence, Innovation Systems and Leadership Development.

Working together, these strategies provide the means to continually refresh a company’s value proposition while making the organizational changes needed for daily improvement and sustainable growth.

We pioneered the implementation of Lean and TPM methodologies in manufacturing in the late 1970s. Since then, we have extended these methodologies across a wide range of industries, including healthcare, finance, and other service industries.

Today, our time-tested management system, motion™ provides organizations with:

- a uniquely comprehensive approach to implementing Lean across an entire enterprise, incorporating assessment, leadership, and business renewal.

- a robust process for innovation to develop an organization-wide capability to create new forms of value – reliably, predictably, repeatedly.

More than simply a Lean consulting firm, Productivity Inc. can provide you with a variety of methodologies to keep your enterprise in motion™.

![]()

THE OHIO STATE UNIVERSITY’S FISHER COLLEGE OF BUSINESS

Since 1916, The Ohio State University’s Fisher College of Business has produced exceptional leaders who meet the challenges of a changing global business environment through creative and effective solutions. As a result, Fisher’s reputation continues to rise and is reflected in rankings which place the college among the top 15 Business Schools in the nation at the undergraduate and graduate levels of public universities.

Today, Fisher College of Business Executive Education continues to provide growth opportunities to business professionals seeking to increase their knowledge, insights and intuition. Their executive-level degree programs are comprehensive, integrative and examine today’s issues from every angle to give you a total business perspective.

To qualify, all participants must have a management sponsor, who will attest to the results achieved in on-the-job assignments. Participants must be affiliated with a manufacturing or service organization actively pursuing process improvement techniques, and should have a fundamental understanding of TPM and lean techniques.

Payment Options: Payment must be received BEFORE the event. This event fills up quickly therefore we cannot confirm reservations until payment is received. Payment installments available. (This option includes a $150 processing fee.)

Participants who successfully complete the four-week training and mentoring program, pass the certification exam, and demonstrate successful implementation in their own facility are certified by Productivity Inc. and the Fisher College of Business as TPM Managers and earn 16 CEUs.

A block of rooms is being held for Productivity Inc. TPMC attendees at The Blackwell Hotel on The Ohio State University campus. Address: 2110 Tuttle Park Place, Columbus, Ohio 43210.

Productivity Inc. attendees receive a reduced rate of $162.00 per night, single or double occupancy. Rate includes hot buffet breakfast. Please call 614.247.4000 or toll-free 866.247.4003 for reservations, and identify yourself as a Productivity Inc. TPMC program attendee. The special rate will be available until four weeks prior to the event; after this date the hotel cannot guarantee availability.

For more information on The Blackwell Hotel, please visit www.theblackwell.com. The hotel is approximately 8 miles from the Columbus International Airport.

Attendee Substitutions: Prior to the start of the program, registrations may be transferred to a colleague without charge. Once the program is underway, substitutions cannot be made.

Attendance: Attendees must attend all modules to qualify for certification.